Understanding what are the benefits of a proactive vs reactive cost approach is critical for businesses aiming to optimize financial performance. This analysis delves into the fundamental differences between these two strategic approaches, exploring how each impacts profitability, resource allocation, and overall business sustainability. We’ll examine the core principles, methodologies, and real-world applications of both proactive and reactive cost management strategies.

A proactive cost approach anticipates and mitigates potential financial risks, while a reactive approach responds to issues as they arise. This exploration will highlight the advantages of a proactive strategy, detailing cost control strategies, implementation procedures, and the influence on decision-making. Furthermore, we will showcase successful case studies and examine the technologies and training necessary to foster a culture of proactive cost management within an organization, offering a comprehensive guide for achieving long-term financial success.

Defining Proactive vs. Reactive Cost Approaches

Understanding the difference between proactive and reactive cost approaches is crucial for effective financial management within any organization. These two strategies represent fundamentally different philosophies towards controlling and minimizing expenses. Choosing the right approach, or a blend of both, significantly impacts a company’s profitability, sustainability, and overall success.

Core Differences and Examples

The primary distinction between proactive and reactive cost approaches lies in their timing and focus. A proactive approach anticipates potential cost issues and implements measures to prevent them. Conversely, a reactive approach addresses cost problems after they have already occurred.For instance, consider a manufacturing company.* Proactive Approach: The company invests in preventative maintenance for its machinery. Regular inspections, scheduled repairs, and proactive part replacements minimize the likelihood of unexpected breakdowns.

This strategy aims to avoid costly downtime and production delays. The goal is to ensure that equipment operates efficiently, minimizing energy consumption and material waste, thereby reducing overall operational costs.* Reactive Approach: The company waits for a machine to break down before initiating repairs. This reactive approach often leads to emergency repairs, expedited shipping of replacement parts (at a premium), and extended periods of production downtime.

These factors significantly increase the overall cost compared to a proactive maintenance strategy. The company may also experience lost sales due to the inability to fulfill orders.Another example involves software development.* Proactive Approach: The development team invests in thorough code reviews, automated testing, and continuous integration to identify and fix bugs early in the development cycle. This approach minimizes the risk of major defects that require costly rework later on.

It also leads to higher software quality and reduces the time to market.* Reactive Approach: The development team focuses on fixing bugs only after the software is released and users report issues. This reactive approach often involves patching the software, issuing updates, and potentially damaging the company’s reputation. It also leads to increased development costs due to the need for bug fixes and customer support.

Definitions and Methodologies

Each approach has a distinct definition, outlining its primary goals and methodologies.* Proactive Cost Approach: This approach focuses on identifying and mitigating potential cost drivers

before* they impact the organization. Its primary goal is to prevent cost overruns, optimize resource allocation, and improve long-term profitability. Methodologies include

Detailed budgeting and forecasting.

Risk assessment and management.

Process optimization and efficiency improvements.

Investing in training and development.

Negotiating favorable contracts with suppliers.

Continuous monitoring and analysis of key performance indicators (KPIs).

Implementation of lean methodologies.

* Reactive Cost Approach: This approach focuses on addressing cost issues

after* they have already occurred. Its primary goal is to minimize the impact of existing cost problems and prevent them from recurring. Methodologies include

Cost reduction initiatives.

Expense control measures.

Identifying and eliminating waste.

Restructuring or downsizing.

Implementing stricter approval processes.

Investigating and resolving cost variances.

Corrective actions to prevent recurrence.

Triggers of Reactive Cost Approaches

Reactive cost approaches are often initiated by specific events or circumstances that signal a problem. The triggers vary across industries, but some common examples include:* Increased operating expenses: A sudden rise in utility bills, raw material costs, or labor expenses can trigger a reactive response.

Decreased profitability

A decline in profit margins or net income often prompts a review of costs.

Budget overruns

Exceeding the allocated budget for a specific project or department.

Customer complaints

Issues related to product quality, delivery delays, or customer service can lead to cost adjustments.

Market changes

Fluctuations in demand, competition, or economic conditions can necessitate cost-cutting measures.

Technological disruptions

The introduction of new technologies or the obsolescence of existing systems can drive cost adjustments.

Unexpected events

Natural disasters, supply chain disruptions, or regulatory changes can trigger a reactive approach.These triggers necessitate swift action to mitigate the negative impact on the organization’s financial performance. For instance, a retail company experiencing a sharp increase in shipping costs due to fuel price hikes might implement a reactive approach by renegotiating shipping contracts, optimizing delivery routes, or adjusting pricing strategies.

Advantages of a Proactive Cost Approach

Adopting a proactive cost approach offers significant advantages over a reactive strategy, particularly in manufacturing and project management. By anticipating potential cost issues and implementing preventative measures, businesses can achieve greater financial stability, improve operational efficiency, and enhance overall profitability. This approach focuses on identifying and mitigating risks before they materialize, leading to more predictable outcomes and a stronger competitive position.

Improved Profitability and Resource Allocation

A proactive cost strategy directly contributes to improved profitability. By proactively managing costs, businesses can identify opportunities to reduce expenses, optimize resource utilization, and increase profit margins. This approach involves a continuous assessment of cost drivers, the implementation of cost-saving initiatives, and the monitoring of key performance indicators (KPIs) to track progress. Furthermore, proactive cost management allows for more efficient resource allocation.

By understanding where costs are incurred and how they impact the bottom line, companies can allocate resources more strategically, investing in areas that yield the highest returns and avoiding wasteful spending. This can lead to better inventory management, optimized production schedules, and more effective marketing campaigns, all contributing to enhanced profitability.

Key Advantages of a Proactive Approach in Manufacturing

A proactive cost approach provides several key advantages specifically within the manufacturing sector. Implementing this approach can significantly improve operational efficiency and financial performance.

- Enhanced Cost Control: A proactive approach enables manufacturers to gain better control over their costs. This involves detailed cost analysis, identifying areas of potential savings, and implementing cost-reduction strategies. For example, a company might proactively negotiate better prices with suppliers, optimize production processes to reduce waste, or invest in energy-efficient equipment to lower utility bills.

- Reduced Waste and Improved Efficiency: By focusing on prevention, manufacturers can minimize waste in all forms, including materials, labor, and energy. Implementing lean manufacturing principles, such as just-in-time inventory management and continuous improvement methodologies (e.g., Kaizen), can significantly reduce waste and enhance overall efficiency. For instance, a manufacturer might implement a system to track and analyze material usage, identifying areas where excess materials are being used or wasted.

- Improved Product Quality: Proactive cost management often involves quality control measures. By implementing quality control systems early in the production process, manufacturers can prevent defects and reduce the need for rework or repairs. This not only saves costs but also improves customer satisfaction. For example, implementing a robust inspection process at various stages of production can catch defects early, minimizing the cost of correcting them later.

- Better Forecasting and Planning: A proactive approach allows for more accurate cost forecasting and improved planning. By analyzing historical data and anticipating future cost trends, manufacturers can develop more realistic budgets and production schedules. This helps to avoid costly surprises and ensures that resources are allocated effectively. For example, using historical data on material costs, labor rates, and overhead expenses to predict future costs and adjust production plans accordingly.

- Increased Competitive Advantage: Manufacturers who proactively manage their costs are better positioned to compete in the market. By controlling costs and improving efficiency, they can offer competitive prices while maintaining profitability. This allows them to attract more customers and gain a larger market share. An example of this is a manufacturer that proactively invests in automation to reduce labor costs and increase production output, thereby improving its competitive pricing.

Minimizing Financial Risks in Project Management

A proactive cost approach significantly minimizes financial risks in project management. By proactively identifying and addressing potential cost overruns, project managers can keep projects on track and within budget.For example, consider a construction project. A proactive approach would involve a detailed risk assessment at the outset, identifying potential cost risks such as material price fluctuations, labor shortages, or unforeseen site conditions.

The project manager would then develop contingency plans and allocate a budget for these risks.

“A study by the Project Management Institute (PMI) found that projects with proactive risk management are significantly more likely to be completed on time and within budget compared to those with reactive risk management.”

This proactive approach contrasts with a reactive approach, where cost issues are addressed only after they arise. This reactive approach can lead to cost overruns, project delays, and ultimately, financial losses.

Disadvantages of a Reactive Cost Approach

A reactive cost approach, while sometimes unavoidable, often leads to significant drawbacks that can negatively impact an organization’s financial health, operational efficiency, and overall competitiveness. Responding to issues as they arise can create a cycle of costly repairs, inefficiencies, and missed opportunities for strategic investment. This section details the specific disadvantages associated with this approach.

Potential for Cost Overruns and Inefficiencies

A reactive cost strategy is inherently prone to cost overruns and operational inefficiencies. Addressing problems after they occur frequently involves expedited solutions, often at a premium price. This contrasts sharply with the cost savings and predictability offered by proactive measures.Here’s how these cost overruns and inefficiencies manifest:* Emergency Repairs: Unexpected failures necessitate immediate action, often requiring overtime pay, premium-priced parts, and rushed service.

For example, a server outage requiring emergency IT support can cost several times more than scheduled maintenance.

Lack of Planning

Without a proactive plan, organizations lack the ability to negotiate favorable rates with vendors or leverage economies of scale. Reactive purchasing typically involves buying at the current market price, which is often higher.

Resource Wastage

Inefficiencies arise from dealing with issues as they surface. This includes downtime, lost productivity, and the need to divert resources from planned projects to address immediate problems. For instance, a reactive approach to software updates may lead to compatibility issues and system crashes, causing significant disruption.

Delayed Investment

Reactive approaches often prioritize immediate fixes over strategic investments that could prevent future problems. This can lead to a cycle of short-term solutions that fail to address the root causes of issues.

Common Pitfalls in IT Infrastructure Management

A reactive strategy in IT infrastructure management is riddled with specific pitfalls that can cripple an organization’s ability to function effectively. These pitfalls stem from a lack of foresight and the inherent unpredictability of responding to crises.Here are three common pitfalls:* Increased Downtime: Reacting to infrastructure failures results in longer periods of downtime. This is because the response time is extended by the need to diagnose the problem, locate resources, and implement a fix.

Downtime directly translates to lost revenue, reduced productivity, and damage to the organization’s reputation.

Security Vulnerabilities

A reactive approach to security often leaves systems vulnerable to attacks. When patches and updates are implemented reactively, there is a delay between the discovery of a vulnerability and its remediation. This window of opportunity is exploited by attackers. For instance, a company that delays patching a known security flaw may find itself the victim of a ransomware attack, leading to significant financial losses and data breaches.

Data Loss Risks

Data loss is a critical concern when adopting a reactive approach. Without proactive backups and disaster recovery plans, a hardware failure, software corruption, or cyberattack can result in the permanent loss of valuable data. Data loss can have devastating consequences, including legal liabilities, damage to customer relationships, and the disruption of business operations.

Decreased Competitiveness

Relying on a reactive cost approach can significantly decrease an organization’s competitiveness. It limits the ability to innovate, respond quickly to market changes, and optimize operations.The impact on competitiveness includes:* Reduced Innovation: Resources are consumed by addressing immediate problems, leaving less time and budget for innovation and development. Competitors with a proactive strategy can invest in new technologies and processes, gaining a competitive edge.

Slower Response Times

A reactive approach hinders the ability to adapt to changing market conditions or customer demands. Delays in addressing issues or implementing changes can lead to lost opportunities and decreased customer satisfaction.

Higher Operational Costs

The cost overruns and inefficiencies associated with a reactive approach make it more difficult to compete on price. Organizations with higher operating costs may struggle to offer competitive pricing, leading to decreased market share.

Damage to Reputation

Frequent failures and disruptions can damage an organization’s reputation, leading to a loss of customer trust and decreased brand loyalty. Customers are more likely to choose competitors with a more reliable and efficient service.

Cost Control Strategies in a Proactive Environment

A proactive cost control approach necessitates a structured and systematic strategy to manage and minimize expenses throughout a project’s lifecycle. This involves anticipating potential cost overruns, implementing preventative measures, and continuously monitoring and adjusting plans. Effective proactive cost control goes beyond simply reacting to issues; it involves actively shaping the financial landscape of a project to achieve optimal cost efficiency.

Design a Comprehensive Cost Control Strategy for a Proactive Environment

Developing a comprehensive cost control strategy in a proactive environment involves several key steps, starting from the initial planning phase and extending throughout the project’s duration. This proactive approach aims to prevent cost overruns before they occur, promoting greater financial predictability and control.A comprehensive cost control strategy includes:* Detailed Project Planning and Budgeting: Establish a realistic and detailed budget at the outset, encompassing all anticipated costs.

This includes labor, materials, equipment, and other expenses. Employing techniques like work breakdown structures (WBS) allows for granular cost allocation and tracking.

Risk Assessment and Management

Identify potential risks that could impact costs, such as material price fluctuations, delays, or unforeseen site conditions. Develop mitigation plans for each identified risk. This proactive approach helps to minimize the impact of potential problems.

Vendor Selection and Management

Implement a rigorous vendor selection process to ensure competitive pricing and quality. Negotiate favorable contracts and establish clear communication channels to manage vendor performance and prevent cost escalation.

Regular Cost Tracking and Reporting

Implement a system for regularly tracking and reporting on project costs. Compare actual costs against the budget, and analyze variances to identify areas of concern. This information allows for timely corrective actions.

Change Order Management

Establish a formal change order process to manage modifications to the project scope. Carefully evaluate the cost implications of each change and ensure proper authorization before implementation.

Value Engineering

Implement value engineering techniques to identify opportunities for cost savings without compromising quality or functionality. This may involve exploring alternative materials, methods, or designs.

Continuous Improvement

Continuously review the cost control process and identify areas for improvement. Analyze past performance, learn from mistakes, and update procedures to enhance cost efficiency in future projects.

Organize the Steps for Implementing a Proactive Cost Control Plan

Implementing a proactive cost control plan requires a systematic approach, broken down into sequential steps to ensure effective execution and monitoring. This organized implementation enhances the probability of achieving the desired cost-saving outcomes.Here are the steps for implementing a proactive cost control plan:

- Establish a Baseline Budget: Develop a detailed budget that serves as the benchmark for cost control. This baseline should be based on a thorough assessment of project requirements and realistic cost estimates.

- Develop a Cost Breakdown Structure (CBS): Create a CBS to categorize and organize project costs. This structure facilitates detailed cost tracking and analysis.

- Identify Potential Risks: Conduct a comprehensive risk assessment to identify potential threats to the budget. This includes factors like material price volatility, labor shortages, and unforeseen site conditions.

- Develop Mitigation Plans: Create plans to address identified risks. These plans may involve contingency budgets, alternative sourcing strategies, or proactive communication protocols.

- Implement Cost Tracking Systems: Implement systems for tracking and reporting project costs. This may involve using project management software, spreadsheets, or other tools to monitor spending against the budget.

- Monitor and Analyze Costs Regularly: Regularly compare actual costs to the budget and identify variances. Analyze these variances to understand the root causes and take corrective actions.

- Manage Change Orders: Establish a formal process for managing change orders. Evaluate the cost implications of each change and ensure proper authorization before implementation.

- Communicate and Collaborate: Foster open communication and collaboration among project stakeholders. This includes regular meetings, progress reports, and transparent sharing of cost information.

- Implement Value Engineering: Identify opportunities for cost savings through value engineering techniques. This may involve exploring alternative materials, methods, or designs.

- Review and Improve: Continuously review the cost control process and identify areas for improvement. This involves analyzing past performance, learning from mistakes, and updating procedures.

Provide Examples of Cost-Saving Techniques That Can Be Used Proactively in the Construction Industry

The construction industry can leverage various proactive cost-saving techniques to optimize project budgets and improve profitability. These techniques focus on preventing cost overruns rather than reacting to them, offering a more sustainable approach to financial management.Here are examples of proactive cost-saving techniques in construction:* Early Procurement: Procure critical materials and equipment early in the project lifecycle to lock in prices and mitigate the risk of price increases.

For instance, if a project requires a significant amount of steel, purchasing it upfront at a fixed price can shield the project from potential market fluctuations.

Design Optimization

Review the design plans for potential cost savings. This could involve using alternative materials, simplifying the design, or optimizing the structural layout. For example, a building design could be modified to reduce the amount of concrete required, thereby lowering material and labor costs.

Lean Construction Principles

Implement lean construction principles to eliminate waste and improve efficiency. This includes optimizing workflows, reducing delays, and improving resource utilization. An example would be implementing just-in-time inventory management to minimize storage costs and material waste.

Value Engineering Workshops

Conduct value engineering workshops early in the project to identify opportunities for cost savings without compromising quality or functionality. These workshops bring together stakeholders to brainstorm alternative solutions.

Energy-Efficient Design

Incorporate energy-efficient design features to reduce long-term operating costs. This includes using energy-efficient lighting, HVAC systems, and insulation. For instance, a building with a well-insulated envelope and efficient windows will require less energy for heating and cooling, resulting in lower utility bills over its lifespan.

Subcontractor Management

Select subcontractors carefully, negotiate favorable contracts, and closely monitor their performance. This includes ensuring that subcontractors adhere to the project schedule and budget.

Technology Adoption

Utilize technology such as Building Information Modeling (BIM) to improve design coordination, detect clashes, and reduce rework. This can lead to significant cost savings. BIM software allows for virtual construction simulations, which can help identify and resolve potential issues before construction begins.

Material Substitution

Identify opportunities to substitute less expensive materials without compromising quality. For example, using recycled materials or locally sourced materials can reduce transportation costs and material expenses.

Pre-fabrication

Utilize pre-fabrication techniques to reduce on-site labor costs and improve construction speed. Pre-fabricated components, such as wall panels or modular bathrooms, can be manufactured off-site and assembled quickly on-site.

Effective Communication and Collaboration

Establish clear communication channels and promote collaboration among all project stakeholders. This includes regular meetings, progress reports, and transparent sharing of cost information. Open communication helps to identify and address potential problems early on.

Implementing a Proactive Cost Management System

Implementing a proactive cost management system requires a structured approach, commitment from all levels of the organization, and the right tools and techniques. This section Artikels a step-by-step procedure, highlights best practices for selecting and utilizing software, and explains the critical role of data analytics in driving informed decisions. A well-implemented system can significantly improve a small business’s financial health and competitiveness.

Procedure for Implementing a Proactive Cost Management System within a Small Business

Implementing a proactive cost management system is a phased process. It should be tailored to the specific needs and resources of the small business. The following steps provide a comprehensive guide:

- Assessment and Planning: Before implementing any system, a thorough assessment of current cost structures, spending patterns, and existing cost management practices is crucial. This phase involves identifying areas where costs are excessive or inefficient and setting clear, measurable cost reduction goals. The plan should include a timeline, budget, and assigned responsibilities.

- Data Collection and Analysis: Gather relevant financial data, including invoices, purchase orders, expense reports, and bank statements. Analyze this data to identify cost drivers, understand spending trends, and pinpoint areas for improvement. Tools like spreadsheets can be used for initial analysis, but consider more advanced software for long-term management.

- Process Optimization: Streamline existing processes to eliminate waste and reduce costs. This may involve negotiating better prices with suppliers, implementing more efficient workflows, or automating manual tasks. For example, a small manufacturing business could optimize its production line to reduce material waste and labor costs.

- Software Selection and Implementation: Choose a cost management software solution that aligns with the business’s specific needs and budget. The implementation phase involves installing the software, configuring it to track relevant data, and training employees on its use.

- Establishment of Cost Control Measures: Implement specific cost control measures based on the analysis and planning phases. This could include setting spending limits, requiring approval for certain expenses, and implementing budgeting and forecasting processes.

- Monitoring and Reporting: Regularly monitor key cost metrics and generate reports to track progress against goals. This involves setting up dashboards and reports that provide real-time insights into spending patterns and cost performance.

- Continuous Improvement: The cost management system should be a dynamic process. Regularly review and update the system, based on performance data and changing business needs. This includes making adjustments to cost control measures, optimizing processes, and refining software usage.

Best Practices for Selecting and Utilizing Cost Management Software Tools

Selecting the right software and utilizing it effectively is essential for a successful proactive cost management system. Several best practices can guide this process:

- Needs Assessment: Define the specific requirements of the business. Identify the features needed, such as budgeting, forecasting, reporting, and integration capabilities with existing accounting systems.

- Vendor Research: Research available software options. Evaluate vendors based on their reputation, customer reviews, pricing, and level of support. Consider cloud-based solutions for ease of access and scalability.

- Pilot Testing: Before committing to a full implementation, conduct a pilot test with a small group of users to evaluate the software’s functionality, usability, and integration capabilities.

- User Training: Provide comprehensive training to all employees who will use the software. This ensures they understand how to input data, generate reports, and utilize the system effectively.

- Customization: Customize the software to meet the specific needs of the business. Configure dashboards, reports, and alerts to track the most relevant cost metrics.

- Data Integration: Integrate the software with existing accounting systems and other relevant data sources. This ensures that data is accurate, up-to-date, and accessible in a centralized location.

- Regular Updates: Stay up-to-date with software updates and new features. This ensures that the business is utilizing the latest technology and benefiting from any performance improvements.

- Data Security: Implement robust security measures to protect sensitive financial data. This includes using strong passwords, encrypting data, and regularly backing up data.

Role of Data Analytics in Supporting a Proactive Cost Management System

Data analytics plays a critical role in supporting a proactive cost management system by providing valuable insights and enabling data-driven decision-making. The effective use of data analytics can transform raw data into actionable intelligence.

- Cost Driver Identification: Data analytics helps identify the primary drivers of costs. By analyzing historical data, businesses can pinpoint the factors that have the most significant impact on spending. For example, a retail business might use data analytics to determine that marketing campaigns on social media are more cost-effective than traditional advertising.

- Trend Analysis: Analyzing historical data helps identify trends in spending patterns. This allows businesses to anticipate future costs and make proactive adjustments to budgets and spending plans. For instance, a restaurant could analyze its food costs over time to anticipate seasonal price fluctuations.

- Predictive Modeling: Data analytics can be used to create predictive models that forecast future costs. This enables businesses to anticipate potential cost overruns and take corrective actions before they occur.

- Performance Measurement: Data analytics provides a basis for measuring the effectiveness of cost control measures. By tracking key performance indicators (KPIs), businesses can assess whether their cost management strategies are achieving their goals.

- Optimization Opportunities: Data analytics can identify opportunities to optimize processes and reduce costs. For example, analyzing purchasing data might reveal opportunities to negotiate better prices with suppliers or consolidate purchases.

- Data Visualization: Data visualization tools transform complex data into easily understandable charts and graphs. This makes it easier for decision-makers to grasp key insights and communicate them to others.

Impact on Decision-Making

A company’s cost approach significantly shapes its strategic decision-making processes. Proactive cost management empowers organizations to make informed choices, leading to better resource allocation, improved profitability, and enhanced long-term sustainability. Conversely, a reactive approach often results in decisions based on immediate pressures, potentially leading to suboptimal outcomes.

Strategic Decision-Making Influenced by a Proactive Cost Approach

A proactive cost approach fundamentally alters the way strategic decisions are made. It moves the focus from simply reacting to costs to actively managing and controlling them. This shift provides valuable insights that inform strategic planning.

- Enhanced Forecasting and Budgeting: Proactive cost management enables more accurate forecasting of future costs. This allows businesses to create realistic budgets, allocate resources effectively, and anticipate potential financial challenges. For example, a manufacturing company using a proactive approach might forecast a rise in raw material costs six months in advance, allowing them to negotiate better prices or find alternative suppliers.

- Improved Investment Decisions: With a clear understanding of all associated costs, proactive cost management facilitates better investment decisions. Companies can evaluate the true cost of projects, assess their potential return on investment (ROI) more accurately, and prioritize projects that offer the best financial outcomes. For instance, when considering a new product line, a proactive approach will factor in all costs from research and development to marketing and distribution, leading to a more informed go/no-go decision.

- Better Pricing Strategies: A comprehensive understanding of costs enables companies to develop more competitive and profitable pricing strategies. Businesses can determine the optimal price points for their products or services, considering both production costs and market demand. For example, a retail business, through a proactive approach, can identify the cost components of each product, allowing it to adjust pricing to maximize profits.

- Risk Mitigation: Proactive cost management helps identify and mitigate financial risks. By monitoring costs closely, businesses can detect potential problems early and take corrective actions before they escalate. For example, a construction company proactively monitoring labor costs can identify and address inefficiencies before they impact project profitability.

Decision-Making Comparison: Proactive vs. Reactive Cost Strategies

The decision-making processes differ significantly between proactive and reactive cost strategies. These differences influence the quality and effectiveness of the decisions made.

| Feature | Proactive Cost Strategy | Reactive Cost Strategy |

|---|---|---|

| Information Availability | Access to detailed and timely cost data; comprehensive cost analysis. | Limited access to cost data; often relies on historical information. |

| Decision Focus | Forward-looking, focused on preventing cost issues. | Backward-looking, focused on addressing existing cost issues. |

| Decision Speed | Decisions made with time for analysis and planning. | Decisions often made under pressure, requiring quick fixes. |

| Decision Quality | Higher quality decisions based on informed analysis. | Lower quality decisions due to limited information and time constraints. |

| Impact on Strategy | Supports long-term strategic goals and objectives. | Often driven by short-term pressures, potentially hindering long-term goals. |

Enabling Better Investment Decisions Through Proactive Cost Management

Proactive cost management is a key enabler for making sound investment decisions. It provides the necessary data and insights to assess the financial viability of potential investments.

- Comprehensive Cost Analysis: A proactive approach involves a thorough analysis of all costs associated with an investment, including direct costs, indirect costs, and opportunity costs. This comprehensive view provides a clear understanding of the true cost of the investment.

- Realistic ROI Projections: By accurately forecasting costs and revenues, proactive cost management allows businesses to create realistic ROI projections. This helps in evaluating the financial attractiveness of an investment and comparing it with other investment opportunities. For example, a tech startup uses a proactive approach to calculate ROI by accurately forecasting the cost of developing new software and comparing that with expected revenue.

- Scenario Planning and Sensitivity Analysis: Proactive cost management enables scenario planning and sensitivity analysis. This allows companies to assess the impact of different cost and revenue scenarios on the investment’s profitability. For instance, a real estate developer can assess the impact of changes in construction costs or rental rates on the profitability of a new building project.

- Improved Resource Allocation: By understanding the costs and potential returns of various investment options, proactive cost management helps companies allocate resources effectively. This leads to better utilization of capital and maximizes the overall financial performance.

Case Studies

Understanding the practical application of proactive cost approaches is best achieved through examining real-world examples. These case studies illuminate the tangible benefits of shifting from reactive to proactive cost management, highlighting the positive impact on organizational performance and financial stability.

Proactive Cost Success Stories: Company X

Company X, a mid-sized manufacturing firm specializing in precision components, faced significant challenges due to fluctuating material costs and inefficient production processes. Their existing cost management approach was largely reactive, responding to cost overruns after they occurred. This led to unpredictable profitability and strained relationships with suppliers. Recognizing the need for change, Company X embarked on a comprehensive initiative to implement a proactive cost management system.

This involved several key strategies:* Supplier Relationship Management: They actively negotiated long-term contracts with key suppliers, securing favorable pricing and stabilizing material costs. This included a detailed analysis of supplier performance and collaborative efforts to identify and implement cost-saving opportunities within the supply chain.

Process Optimization

Company X invested in lean manufacturing principles, streamlining production processes and reducing waste. This involved implementing real-time monitoring of production efficiency and identifying bottlenecks for immediate correction.

Value Engineering

They incorporated value engineering techniques during the design phase of new products, focusing on minimizing material usage and simplifying manufacturing processes without compromising product quality. This included a cross-functional team review of all new product designs.

Technology Adoption

They adopted advanced cost accounting software to provide real-time visibility into costs and enable data-driven decision-making. This included implementing a dashboard system to track key performance indicators (KPIs) related to cost control.The transition to a proactive cost approach yielded substantial improvements, demonstrated by the following before-and-after metrics:

| Metric | Before (Reactive) | After (Proactive) | Change |

|---|---|---|---|

| Material Cost as % of Revenue | 60% | 52% | -8% |

| Production Waste | 10% | 4% | -6% |

| On-Time Delivery Rate | 85% | 95% | +10% |

| Profit Margin | 8% | 15% | +7% |

The data illustrates a clear shift towards improved financial performance and operational efficiency. The proactive approach allowed Company X to better manage its costs, improve profitability, and enhance its competitiveness within the market.

Key Lessons Learned from Proactive Cost Implementations

Several critical lessons emerged from the successful implementation of proactive cost management strategies, providing valuable insights for other organizations seeking similar improvements.* Executive Sponsorship is Essential: Successful implementation requires strong support from senior management. Their commitment ensures the allocation of necessary resources and promotes a culture of cost consciousness throughout the organization.

Cross-Functional Collaboration is Crucial

Proactive cost management is not solely the responsibility of the finance department. It requires collaboration between various departments, including procurement, production, engineering, and sales. This ensures a holistic approach to cost control.

Data-Driven Decision Making is Paramount

Accurate and timely data is essential for identifying cost drivers, monitoring performance, and making informed decisions. Investing in robust cost accounting systems and analytics capabilities is a critical success factor.

Continuous Improvement is Key

Proactive cost management is an ongoing process, not a one-time project. Organizations must continuously monitor their costs, identify areas for improvement, and adapt their strategies to changing market conditions.

Employee Training and Engagement

Employees at all levels need to understand the importance of cost management and be actively involved in identifying and implementing cost-saving initiatives. Providing training and fostering a culture of cost awareness is crucial.

Focus on Prevention

The emphasis should be on preventing cost overruns rather than simply reacting to them. This involves proactive measures such as supplier negotiations, process optimization, and value engineering.By embracing these lessons, organizations can significantly improve their cost management practices and achieve sustainable financial performance.

Cost Forecasting and Budgeting

Effective cost forecasting and budgeting are crucial components of a successful proactive cost approach. They provide the foundation for informed decision-making, resource allocation, and overall financial stability. Accurate predictions and well-defined budgets allow organizations to anticipate potential cost fluctuations, identify areas for improvement, and ultimately achieve their financial goals.

Design of a Cost Forecasting Model Suitable for a Proactive Cost Environment

A proactive cost environment necessitates a sophisticated cost forecasting model that goes beyond simply extrapolating past trends. The model should incorporate a forward-looking perspective, considering various factors that can influence future costs.To create a robust cost forecasting model, consider the following elements:

- Data Collection and Analysis: Begin by gathering comprehensive historical cost data, including direct materials, labor, overhead, and other relevant expenses. Analyze this data to identify cost drivers and patterns. This analysis helps understand the relationships between different cost components and business activities.

- External Factor Integration: Incorporate external factors that can affect costs, such as:

- Economic Indicators: Inflation rates, interest rates, and currency exchange rates can significantly impact material prices, labor costs, and overall project expenses.

- Market Trends: Understanding industry-specific trends, such as changes in raw material availability or technological advancements, is vital.

- Supplier Relationships: Consider the impact of supplier contracts, potential price increases, and the reliability of the supply chain.

- Scenario Planning: Develop multiple scenarios to assess the potential impact of different variables. This allows for the creation of contingency plans and the ability to adapt to unexpected changes. For example, a company might forecast costs under optimistic, most likely, and pessimistic scenarios, considering factors like fluctuating raw material prices or potential supply chain disruptions.

- Forecasting Techniques: Employ appropriate forecasting techniques based on the nature of the data and the desired level of accuracy.

- Regression Analysis: Useful for identifying the relationship between cost and various independent variables. For instance, a regression model could predict labor costs based on production volume and the complexity of the products.

- Time Series Analysis: Effective for identifying trends and seasonality in historical cost data. This method helps in forecasting future costs based on past patterns.

- Expert Judgment: Involve experienced professionals who can provide insights based on their industry knowledge and expertise. This is particularly useful when dealing with complex or uncertain factors.

- Continuous Monitoring and Refinement: Regularly monitor the performance of the forecasting model, comparing predicted costs with actual results. Refine the model over time by incorporating new data, adjusting parameters, and incorporating feedback.

Differences Between Proactive and Traditional Budgeting Methods

Proactive budgeting fundamentally differs from traditional budgeting methods in its approach and objectives. Traditional budgeting often focuses on historical data and incremental changes, while proactive budgeting emphasizes future-oriented planning and strategic alignment.Key distinctions include:

- Focus:

- Traditional Budgeting: Primarily focused on controlling costs and achieving short-term financial targets.

- Proactive Budgeting: Concentrates on anticipating future costs, identifying potential risks and opportunities, and aligning budgets with strategic goals.

- Data Utilization:

- Traditional Budgeting: Heavily relies on historical data and past performance.

- Proactive Budgeting: Integrates both historical data and future-oriented factors, such as market trends, economic forecasts, and strategic initiatives.

- Time Horizon:

- Traditional Budgeting: Typically involves annual or quarterly budgets.

- Proactive Budgeting: Often considers a longer time horizon, allowing for more strategic planning and investment decisions.

- Flexibility:

- Traditional Budgeting: Less flexible and often resistant to changes.

- Proactive Budgeting: More adaptable to changing circumstances, with the ability to adjust budgets based on new information and evolving market conditions.

- Process:

- Traditional Budgeting: Often a top-down process, with budgets dictated by senior management.

- Proactive Budgeting: More collaborative, involving input from various departments and stakeholders.

Importance of Accurate Forecasting in a Proactive Cost Strategy

Accurate cost forecasting is paramount to the success of a proactive cost strategy. It serves as the cornerstone for informed decision-making, effective resource allocation, and proactive risk management.The benefits of accurate forecasting include:

- Informed Decision-Making: Accurate forecasts provide a reliable basis for making strategic decisions. For example, knowing the anticipated cost of raw materials allows a company to decide whether to increase production, negotiate better prices with suppliers, or explore alternative materials.

- Effective Resource Allocation: Accurate forecasts enable businesses to allocate resources efficiently. By anticipating future costs, companies can ensure they have sufficient funds available for essential activities and investments.

- Proactive Risk Management: Accurate forecasts help organizations identify potential cost risks early on. For instance, if a forecast indicates a significant increase in energy costs, the company can proactively explore energy-saving measures or negotiate fixed-price contracts.

- Improved Profitability: By accurately forecasting costs and managing them effectively, companies can improve profitability. This involves controlling expenses, optimizing resource utilization, and making informed pricing decisions.

- Enhanced Strategic Planning: Accurate forecasts provide the foundation for effective strategic planning. By understanding future cost trends, companies can develop long-term strategies, make informed investment decisions, and achieve their financial goals.

- Enhanced Investor Confidence: Companies that demonstrate accurate forecasting and effective cost management are often viewed more favorably by investors.

For instance, consider a manufacturing company that forecasts a 15% increase in the cost of steel over the next year. Based on this forecast, the company could take several proactive steps:

Negotiate long-term contracts with suppliers to lock in favorable prices. Explore alternative materials that are less susceptible to price fluctuations. Adjust pricing strategies to maintain profitability.

Without accurate forecasting, the company might be caught off guard by the rising steel prices, leading to reduced profitability and potentially damaging its competitive position.

Technology and Tools for Proactive Cost Management

Proactive cost management heavily relies on technology and specialized tools to gather, analyze, and act upon cost-related data. These technologies empower businesses to move beyond reactive measures and implement predictive strategies for cost control. The automation capabilities of these tools not only improve efficiency but also provide valuable insights that drive better decision-making.

Technologies and Tools Supporting Proactive Cost Management

Several technologies and tools are essential for enabling proactive cost management. These technologies help in data collection, analysis, and forecasting, which are crucial for anticipating and mitigating cost overruns.

- Enterprise Resource Planning (ERP) Systems: ERP systems integrate various business processes, including finance, procurement, and manufacturing. They provide a centralized platform for tracking costs across different departments and projects.

- Cost Management Software: Dedicated cost management software offers advanced features for budgeting, forecasting, variance analysis, and reporting. These tools often integrate with other systems to provide a holistic view of costs.

- Business Intelligence (BI) and Data Analytics Tools: BI tools and data analytics platforms enable businesses to analyze large datasets, identify cost trends, and generate actionable insights. They provide dashboards and reports that visualize cost performance.

- Cloud Computing: Cloud-based solutions offer scalability, flexibility, and cost-effectiveness for cost management. Cloud platforms allow businesses to access cost management tools and data from anywhere.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms can automate cost forecasting, identify anomalies, and optimize resource allocation. They can analyze historical data to predict future costs.

Automating Cost Control Processes

Technology plays a vital role in automating various cost control processes, reducing manual effort, and improving accuracy. Automation ensures timely access to cost information, enabling proactive responses to potential issues.

- Automated Data Collection: Technology can automate the collection of cost data from various sources, such as invoices, timesheets, and purchase orders. This reduces the risk of human error and speeds up data entry.

- Automated Reporting and Dashboards: Cost management software can automatically generate reports and dashboards that visualize cost performance. These reports provide real-time insights into cost trends and variances.

- Automated Budgeting and Forecasting: AI and ML algorithms can automate the budgeting and forecasting processes. These tools can analyze historical data to predict future costs and identify potential cost overruns.

- Automated Invoice Processing: Technologies like Optical Character Recognition (OCR) can automate invoice processing, reducing manual effort and improving accuracy.

- Automated Variance Analysis: Systems can automatically compare actual costs against budgeted costs and highlight variances. This allows businesses to identify and address cost deviations quickly.

Features of Cost Management Software

Cost management software is specifically designed to support proactive cost control. Its features go beyond simple tracking and offer functionalities that enable businesses to anticipate, manage, and optimize costs.

- Budgeting and Forecasting: Cost management software provides robust budgeting and forecasting capabilities. It allows users to create detailed budgets, forecast future costs, and simulate different scenarios.

- Variance Analysis: This feature compares actual costs against budgeted costs and highlights variances. It provides insights into the reasons for cost deviations and enables businesses to take corrective actions.

- Real-Time Cost Tracking: Cost management software offers real-time cost tracking, providing up-to-date information on costs. This allows businesses to monitor costs closely and identify potential issues early.

- Reporting and Analytics: The software generates comprehensive reports and dashboards that visualize cost performance. It provides insights into cost trends, variances, and other key metrics.

- Integration with Other Systems: Cost management software integrates with other systems, such as ERP and accounting software. This allows businesses to consolidate cost data from various sources and gain a holistic view of costs.

- Alerts and Notifications: The software can send alerts and notifications when costs exceed certain thresholds or when significant variances occur. This allows businesses to take proactive action to address cost issues.

- Scenario Planning: Enables the creation of multiple “what-if” scenarios to analyze the potential cost implications of different business decisions, aiding in proactive planning and risk management.

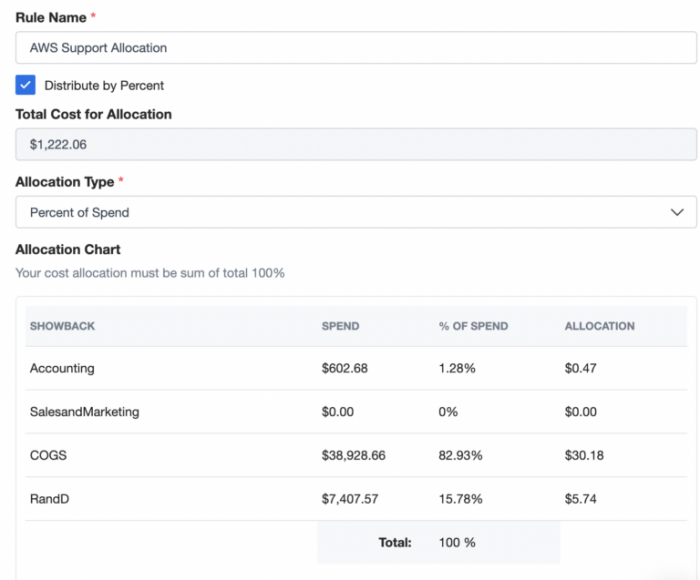

- Cost Allocation: Facilitates the assignment of costs to specific projects, departments, or products, providing detailed cost breakdowns and supporting informed decision-making.

Training and Education

A successful shift to a proactive cost management approach necessitates a robust training and education program. This program should be designed to equip employees at all levels with the knowledge, skills, and mindset needed to identify, prevent, and control costs effectively. This proactive approach empowers employees to take ownership of cost-related activities, contributing to a culture of continuous improvement and financial prudence.

Training Requirements for a Proactive Cost Management Culture

Fostering a proactive cost management culture requires a multi-faceted training approach. This involves various training programs and resources to ensure employees are well-versed in the principles and practices of proactive cost management. The specific training needs will vary depending on the employee’s role and responsibilities within the organization.

- Foundational Training: This introductory training provides a basic understanding of cost management principles. It covers the differences between proactive and reactive approaches, the importance of cost control, and the benefits of a proactive strategy. This training should be mandatory for all employees.

- Role-Specific Training: Tailored training programs should be developed for specific roles. For example:

- Finance Professionals: Training on advanced cost accounting techniques, budgeting and forecasting, variance analysis, and financial modeling.

- Project Managers: Training on project cost estimation, project budgeting, earned value management (EVM), and risk management.

- Procurement Professionals: Training on strategic sourcing, negotiation techniques, supplier relationship management, and cost-benefit analysis.

- Operations Managers: Training on process optimization, waste reduction, lean manufacturing principles, and efficiency improvements.

- Technology and Tools Training: Employees should receive training on any software or tools used for cost management, such as enterprise resource planning (ERP) systems, cost tracking software, and data analytics platforms. This includes understanding how to input data accurately, generate reports, and interpret the results.

- Soft Skills Training: Training on communication, collaboration, problem-solving, and critical thinking is crucial. Employees need to effectively communicate cost-related issues, work collaboratively with colleagues, and analyze data to identify cost-saving opportunities.

- Continuous Learning: Ongoing training and development are essential to keep employees updated on the latest cost management trends, technologies, and best practices. This can include workshops, seminars, webinars, and online courses.

Plan for Educating Employees on Proactive Cost Management

A structured plan is essential for effectively educating employees on the principles of proactive cost management. This plan should be comprehensive, ongoing, and tailored to the organization’s specific needs and goals.

- Needs Assessment: Before implementing any training program, conduct a needs assessment to identify the current knowledge and skill gaps among employees. This can be done through surveys, interviews, and performance reviews.

- Develop Training Materials: Create comprehensive training materials, including presentations, manuals, case studies, and interactive exercises. The materials should be clear, concise, and easy to understand. Consider using a variety of formats, such as videos, infographics, and simulations, to cater to different learning styles.

- Training Delivery: Deliver the training through various methods, such as:

- Classroom Training: Instructor-led sessions provide opportunities for interaction and discussion.

- Online Learning: E-learning modules offer flexibility and accessibility.

- On-the-Job Training: Practical experience and mentorship provide hands-on learning.

- Workshops and Seminars: Interactive sessions to address specific topics and challenges.

- Pilot Program: Before rolling out the training to the entire organization, conduct a pilot program with a small group of employees. This will allow you to test the training materials and delivery methods and make any necessary adjustments.

- Communication and Promotion: Communicate the importance of the training and its benefits to all employees. Promote the training through various channels, such as email, newsletters, and company intranet. Highlight success stories and recognize employees who demonstrate proactive cost management behaviors.

- Evaluation and Feedback: Regularly evaluate the effectiveness of the training program. Collect feedback from employees through surveys, quizzes, and performance reviews. Use the feedback to make improvements to the training program.

Employee Empowerment and a Proactive Cost Approach

Employee empowerment is a critical element of a successful proactive cost approach. When employees are empowered, they are given the authority and responsibility to make decisions and take actions that impact costs. This leads to a more engaged and motivated workforce that is actively involved in identifying and implementing cost-saving initiatives.

- Decision-Making Authority: Empower employees by giving them the authority to make decisions related to their work, such as purchasing supplies, approving expenses, and implementing process improvements. This encourages them to take ownership of their responsibilities and make cost-conscious decisions.

- Information Access: Provide employees with access to the information they need to make informed decisions, such as cost data, performance metrics, and budget information. Transparency is key to fostering a culture of accountability and cost awareness.

- Training and Development: Invest in training and development programs to equip employees with the skills and knowledge they need to make effective cost management decisions. This includes training on cost accounting, budgeting, and financial analysis.

- Recognition and Rewards: Recognize and reward employees who demonstrate proactive cost management behaviors. This can include bonuses, promotions, or public acknowledgment of their contributions.

- Feedback and Communication: Establish a system for providing regular feedback to employees on their performance and cost-related activities. Encourage open communication and collaboration to facilitate the sharing of ideas and best practices.

- Example: Consider a manufacturing company that empowers its production line workers to identify and implement waste reduction strategies. The company provides the workers with data on material usage and waste generation. The workers are then empowered to suggest and implement changes to the production process that reduce waste and save costs. As a result, the company experiences a significant reduction in material costs and improved profitability.

This example highlights how empowering employees at the operational level can lead to significant cost savings.

End of Discussion

In conclusion, mastering the art of what are the benefits of a proactive vs reactive cost approach is essential for navigating the complexities of modern business. By embracing a proactive strategy, businesses can significantly improve profitability, minimize risks, and make more informed decisions. This guide has provided a comprehensive overview of the benefits of proactive cost management, equipping you with the knowledge and tools to implement a robust and effective cost control system, leading to sustainable financial health and long-term success.

FAQ Resource

What is the primary goal of a proactive cost approach?

The primary goal is to prevent cost overruns and optimize resource allocation by anticipating and addressing potential financial risks before they occur.

How does a proactive approach differ from a reactive one in project management?

A proactive approach involves detailed planning, risk assessment, and continuous monitoring, while a reactive approach addresses cost issues only after they surface, often leading to higher expenses and project delays.

What are some key technologies used in proactive cost management?

Technologies include cost management software, data analytics tools, and automation platforms that provide real-time insights and streamline cost control processes.

How can a small business implement a proactive cost management system?

A small business can start by defining clear cost objectives, selecting appropriate software, implementing regular reporting, and training employees on proactive cost management principles.

What role does employee training play in a proactive cost approach?

Training ensures that employees understand cost management principles, empowering them to identify and address potential cost issues proactively, thus fostering a cost-conscious culture.